Introduction

Stainless steel rods are critical components in the construction and engineering industries. Known for their exceptional strength, durability, and resistance to corrosion, these rods are used in various applications, from structural support to precision machinery. In this blog, we will explore the numerous advantages of stainless steel rods, their applications, and why they are indispensable for modern engineering.

What Are Stainless Steel Rods?

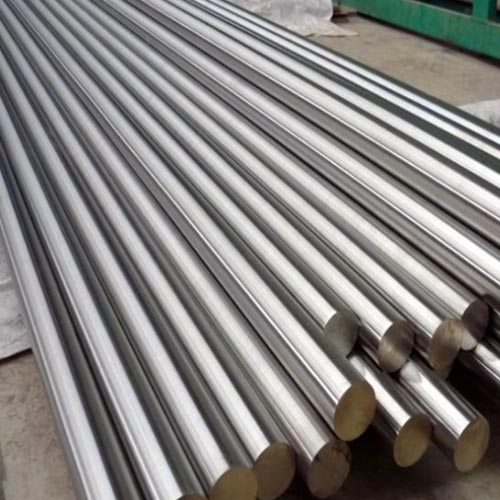

Stainless steel rods are long, cylindrical metal products made from stainless steel, an alloy of iron, carbon, and at least 10.5% chromium. This composition gives stainless steel its remarkable properties, making it ideal for various applications. Stainless steel rods come in different grades and finishes, allowing engineers and architects to select the most suitable type for specific projects.

Properties of Stainless Steel Rods

The properties of stainless steel rod can vary depending on the grade and treatment. Below are some key properties:

| Property | Description |

|---|---|

| Corrosion Resistance | Excellent, even in harsh environments |

| Strength | High tensile and yield strength |

| Durability | Long-lasting and low maintenance |

| Heat Resistance | Maintains integrity at high temperatures |

| Aesthetic Appeal | Attractive finish, suitable for visible applications |

Advantages of Using Stainless Steel Rods

Corrosion Resistance

One of the most significant advantages of stainless steel rods is their corrosion resistance. The chromium content forms a passive layer of chromium oxide on the surface, preventing rust and degradation. This property makes stainless steel rods ideal for outdoor and marine applications.

Strength and Durability

Stainless steel rods exhibit superior strength compared to other materials like aluminum or carbon steel. They can withstand significant loads and stresses, making them perfect for structural components in buildings, bridges, and other engineering projects.

Versatility

Stainless steel rods can be used in various applications, from construction to manufacturing. Their versatility extends to different industries, including automotive, aerospace, and food processing. This adaptability makes them a favorite among engineers and architects.

Low Maintenance

Due to their resistance to corrosion and staining, stainless steel rod require minimal maintenance. This characteristic not only saves time and resources but also contributes to the longevity of structures and components.

Aesthetic Appeal

With their shiny, attractive finish, stainless steel rod can enhance the visual appeal of structures. This is especially important in architectural projects where aesthetics play a significant role.

Applications of Stainless Steel Rods in Construction and Engineering

Stainless steel rods find applications across various sectors. Here are some notable uses:

Structural Support

Stainless steel rod are widely used in structural applications due to their strength and durability. They are often employed in beams, columns, and frameworks that require robust support.

Fasteners and Connectors

In construction, stainless steel rod are frequently used to manufacture bolts, screws, and other fasteners. Their corrosion resistance ensures that these components remain reliable over time.

Reinforcement Bars

Stainless steel rods serve as reinforcement bars (rebars) in concrete structures. Their inclusion enhances the tensile strength of concrete, which is inherently weak in tension.

Piping and Tubing

In engineering, stainless steel rod are often transformed into piping and tubing. Their resistance to heat and corrosion makes them ideal for transporting liquids and gases in various industries.

Architectural Elements

Stainless steel rods are also used in architectural elements like railings, handrails, and decorative features. Their aesthetic appeal and durability contribute to modern architectural designs.

| Application | Description |

|---|---|

| Structural Support | Beams and columns |

| Fasteners and Connectors | Bolts and screws |

| Reinforcement Bars | Used in concrete |

| Piping and Tubing | Transporting fluids |

| Architectural Elements | Railings and decorative features |

Choosing the Right Stainless Steel Rod

Selecting the appropriate stainless steel rod for a project involves considering various factors:

Grade

Different grades of stainless steel offer varying levels of strength, corrosion resistance, and temperature tolerance. Common grades include:

- 304: General-purpose, good corrosion resistance.

- 316: Enhanced corrosion resistance, ideal for marine environments.

- 410: Good strength and wear resistance.

Diameter and Length

The diameter and length of the stainless steel rod should match the structural requirements of the project. Engineers often calculate these dimensions based on load-bearing needs.

Finish

The finish of stainless steel rod can affect their aesthetic appeal and performance. Common finishes include polished, brushed, and matte. The choice often depends on the project’s requirements.

Cost Considerations for Stainless Steel Rods

While stainless steel rods may have a higher upfront cost compared to other materials, their long-term benefits often outweigh initial investments. Factors influencing costs include:

- Material grade: Higher-grade materials typically cost more.

- Quantity: Bulk purchases may reduce per-unit costs.

- Processing: Custom fabrication or finishes can increase costs.

| Factor | Cost Influence |

|---|---|

| Material Grade | Higher grades are more expensive |

| Quantity | Bulk discounts available |

| Processing | Customization adds to costs |

Conclusion

Stainless steel rods are essential for construction and engineering due to their strength, durability, and resistance to corrosion. Their versatility makes them suitable for various applications, from structural support to architectural elements. While the initial costs may be higher than other materials, the long-term benefits and minimal maintenance requirements justify the investment. As we continue to advance in technology and construction practices, the importance of stainless steel rods in building resilient structures cannot be overstated.

FAQ

What are stainless steel rods primarily used for?

Stainless steel rods are primarily used for structural support, fasteners, reinforcement bars, piping, and architectural elements.

How do I choose the right grade of stainless steel rod?

Choosing the right grade involves considering factors like corrosion resistance, strength requirements, and the project’s environmental conditions.

Are stainless steel rod worth the investment?

Yes, stainless steel rod often offer long-term benefits such as durability and low maintenance costs, making them a worthwhile investment.

Can stainless steel rod be recycled?

Absolutely! Stainless steel is highly recyclable, making it an environmentally friendly choice in construction and engineering.

What are the most common grades of stainless steel used in construction?

The most common grades include 304, 316, and 410, each with specific properties suited for different applications.

How do stainless steel rods compare to other materials?

Stainless steel rods generally outperform materials like aluminum and carbon steel in terms of strength, durability, and corrosion resistance.

What factors influence the cost of stainless steel rods?

Factors include material grade, quantity purchased, and any processing or customization required for the rods.