Introduction

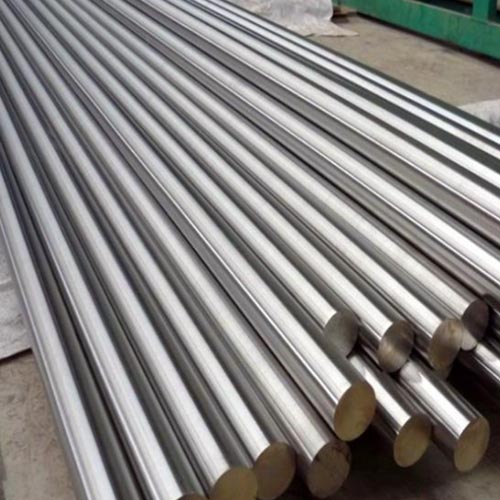

In contemporary construction projects, selecting the right materials is crucial for ensuring longevity, safety, and aesthetic appeal. Stainless rods, renowned for their exceptional strength and corrosion resistance, have become indispensable components in modern construction practices. This blog delves into the reasons why stainless rod are pivotal in today’s construction industry, emphasizing their properties, diverse applications, and advantages over conventional materials.

Properties of Stainless Rods

Stainless rods are primarily composed of chromium, nickel, and other alloys, imparting them with several advantageous properties:

- Corrosion Resistance: Stainless rods exhibit remarkable resistance to corrosion, making them ideal for environments prone to moisture, salt, and chemical exposure.

- High Strength: They offer superior strength compared to materials like carbon steel, providing structural integrity and reliability.

- Aesthetic Appeal: Available in various finishes, stainless rod enhance architectural designs with their sleek appearance and ability to maintain a pristine look over time.

Stainless rods are classified into different grades (e.g., 304, 316) depending on their alloy composition, each tailored for specific applications ranging from structural reinforcement to decorative elements.

Applications in Construction

Stainless rods find extensive use across various construction sectors:

- Reinforcement in Concrete: In reinforced concrete structures, stainless rod prevent corrosion-induced deterioration, prolonging the lifespan of bridges, buildings, and infrastructure.

- Architectural Uses: They are employed in architectural features such as facades, handrails, and cladding due to their aesthetic versatility and durability.

- Industrial Applications: Stainless rod are vital in industrial settings for their ability to withstand harsh conditions without compromising performance.

Advantages Over Other Materials

Comparative advantages of stainless rod over alternative materials are significant:

- Durability: Stainless rod exhibit superior durability, outlasting traditional materials like carbon steel by resisting rust and degradation.

- Environmental Impact: They are environmentally friendly and recyclable, contributing to sustainable construction practices.

- Cost Efficiency: Despite initial higher costs, stainless rod offer long-term cost savings through reduced maintenance and replacement expenses.

Case Studies and Examples

Real-world applications demonstrate the effectiveness of stainless rod:

- Infrastructure Projects: Examples include bridges and dams where stainless rod enhance structural stability and longevity.

- High-Rise Buildings: Stainless rod are crucial in tall buildings for reinforcing concrete and ensuring structural resilience.

- Marine and Coastal Structures: Their corrosion resistance makes stainless rod indispensable in marine environments, enduring exposure to seawater and saline air.

Performance in Extreme Conditions

Stainless rods excel under challenging circumstances:

- High Temperatures: They maintain strength and integrity at elevated temperatures, suitable for applications in industrial furnaces and fire-resistant structures.

- Corrosive Environments: Stainless rod resist corrosion from acids, alkalis, and industrial pollutants, ensuring reliability in harsh chemical environments.

- Seismic Resilience: Their flexibility and durability make stainless rod ideal for seismic retrofitting and earthquake-resistant construction.

Table: Comparison of Stainless Rods with Other Materials

| Property | Stainless Rods | Carbon Steel | Aluminum |

|---|---|---|---|

| Corrosion Resistance | High | Low | Moderate |

| Strength | High | High | Moderate |

| Weight | Moderate | High | Low |

| Cost | Moderate-High | Low | High |

| Sustainability | Recyclable | Recyclable | Recyclable |

Conclusion

Stainless rods are indispensable in modern construction due to their unparalleled combination of strength, durability, and aesthetic appeal. Their resistance to corrosion and ability to withstand extreme conditions make them the material of choice for architects, engineers, and developers aiming to create sustainable and resilient structures. By leveraging stainless rods, construction projects can achieve superior performance and longevity while minimizing environmental impact and lifecycle costs.

FAQ

Q: Are stainless rods more expensive than carbon steel rods?

A: Yes, stainless rods generally have a higher upfront cost due to their superior properties and alloy composition. However, they offer significant long-term savings through reduced maintenance and replacement costs.

Q: Can stainless rod be used in marine environments?

A: Absolutely. Stainless rod are highly resistant to corrosion from saltwater and are commonly utilized in marine construction, offshore platforms, and coastal infrastructure projects.

Q: What finishes are available for stainless rods?

A: Stainless rods can be finished in various ways, including brushed, satin, and mirror finishes, providing architects and designers with flexibility in achieving desired aesthetics.

Q: How do stainless rod compare to fiberglass rods in construction?

A: Stainless rod surpass fiberglass rods in strength and durability, making them suitable for heavy structural applications where robust reinforcement is required.