Introduction

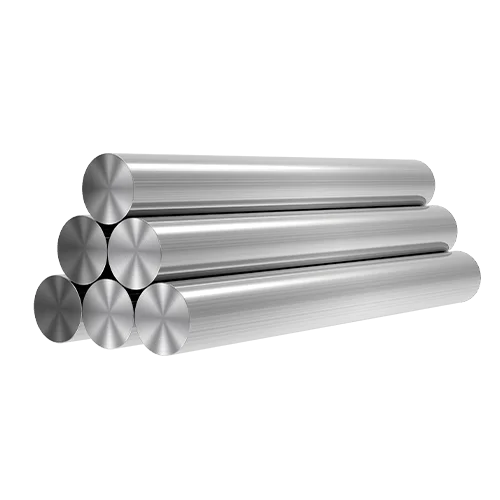

In the realm of industrial applications, selecting the right materials can significantly impact the performance and longevity of components. One such crucial material is the 304 stainless round bar. This blog explores the numerous benefits and applications of 304 stainless round bars in various industrial settings.

What is 304 Stainless Round Bar?

304 stainless steel is a versatile material known for its excellent corrosion resistance, high-temperature strength, and ease of fabrication. The round bar form of 304 stainless steel offers specific advantages in applications requiring durability and aesthetic appeal.

Properties of 304 Stainless Round Bar

| Property | Description |

|---|---|

| Corrosion Resistance | Resistant to corrosion in various environments, including acidic and marine. |

| Strength | High tensile and yield strength suitable for structural applications. |

| Formability | Easily formed and fabricated into different shapes and sizes. |

| Temperature Resistance | Maintains strength and integrity at high temperatures. |

| Aesthetic Appeal | Smooth surface finish ideal for decorative applications. |

Applications of 304 Stainless Round Bar

304 stainless round bars find widespread use across diverse industrial sectors:

- Construction: In construction, 304 stainless round bars are preferred for structural supports due to their excellent strength and corrosion resistance, which ensure stability and durability of buildings and infrastructure. Handrails made from 304 stainless round provide both safety and aesthetic appeal, meeting architectural design requirements while maintaining longevity in various weather conditions.

- Food Industry: In the food industry, equipment and machinery made from 304 stainless round bars are crucial for maintaining sanitary conditions. The material’s non-reactive surface prevents contamination of food products, making it suitable for processing and packaging environments where hygiene is paramount. Its easy-clean properties and resistance to corrosion from food acids and cleaning chemicals further enhance its suitability for prolonged use in food processing facilities.

- Chemical Processing: 304 stainless round play a vital role in chemical processing applications where resistance to corrosion is essential. They are utilized in the construction of tanks, piping systems, and valves that handle corrosive chemicals and solutions. The material’s durability and reliability under harsh chemical environments ensure operational safety and longevity, reducing maintenance costs and downtime associated with equipment failures.

- Automotive: In the automotive industry, 304 stainless round bars are utilized in exhaust systems, where they withstand high temperatures and corrosive exhaust gases. The material’s strength and resistance to oxidation make it an ideal choice for ensuring durability and performance in exhaust components. Additionally, 304 stainless steel is used in automotive trim and structural components, contributing to both aesthetic appeal and structural integrity of vehicles.

- Medical: 304 stainless round bars are indispensable in the medical field for manufacturing surgical instruments and equipment. The material’s biocompatibility and resistance to corrosion make it suitable for sterile environments and repeated sterilization processes without compromising performance. Its smooth surface finish facilitates easy cleaning and maintenance, ensuring hygienic standards required in surgical procedures and medical device manufacturing.

Advantages in Industrial Use

The use of 304 stainless round bars offers several key advantages:

- Cost-Effective: Long-term cost savings due to minimal maintenance and replacement.

- Durability: Resistant to wear and tear, extending service life.

- Hygienic: Suitable for food and medical applications due to its non-reactive properties.

- Versatility: Adaptable to various manufacturing processes and applications.

Case Studies and Examples

Case Study 1: Structural Applications

In a construction project, 304 stainless round bars were used in load-bearing structures, providing durability and aesthetic appeal while minimizing maintenance costs over the building’s lifecycle.

Case Study 2: Chemical Industry

A chemical processing plant utilized 304 stainless round bars in their corrosive environment, demonstrating prolonged resistance to chemical exposure and maintaining structural integrity.

Environmental Considerations

304 stainless steel’s recyclability not only supports sustainable manufacturing practices but also reduces the demand for raw materials, thereby conserving natural resources. The recycling process of 304 stainless steel consumes less energy compared to producing new steel, further lowering its carbon footprint and overall environmental impact. By promoting the reuse of stainless steel scrap, industries contribute to circular economy principles, where materials are continuously circulated through closed-loop systems, minimizing waste generation and landfill contributions. This sustainable approach aligns with global efforts towards environmental stewardship and resource conservation in industrial sectors worldwide.

Conclusion

In conclusion, the versatility and durability of 304 stainless round bars make them indispensable in various industrial applications. From construction to chemical processing, their corrosion resistance and mechanical properties ensure reliable performance and longevity. Choosing 304 stainless round bars can lead to cost savings and enhanced operational efficiency across different sectors.

FAQ

Q: What are the main advantages of using 304 stainless round bars?

A: 304 stainless round bars offer excellent corrosion resistance, high strength, and ease of fabrication, making them ideal for diverse industrial applications.

Q: Can 304 stainless round bars be used in food processing equipment?

A: Yes, due to their non-reactive nature and hygienic properties, 304 stainless round bars are commonly used in the food industry.

Q: How does 304 stainless round bar compare to other stainless steels?

A: Compared to other grades, 304 stainless steel offers good balance in corrosion resistance, strength, and cost-effectiveness, making it a preferred choice for many applications.