Introduction

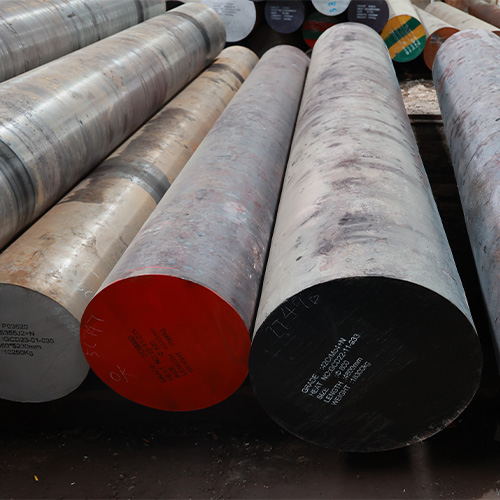

Round bar steel is a versatile metal product with a circular cross-section. It’s produced from carbon steel and is widely used in construction, manufacturing, and engineering applications. Due to its strength, durability, and malleability, round steel is an essential material in numerous industries.

Why Choose Round Bar Steel?

- Exceptional Tensile Strength: Round bar steel offers exceptional tensile strength, making it ideal for applications that require high load-bearing capacity. It can withstand significant forces without breaking or deforming, ensuring structural integrity and safety.

- Superior Durability: Known for its resistance to wear and tear, round bar steel maintains its structural integrity and performance over time. It is a reliable choice for applications where long-term durability is crucial, such as in construction and manufacturing.

- Unparalleled Versatility: The circular cross-section of round steel makes it adaptable to various shapes and sizes. It can be easily formed into different profiles, such as square, rectangular, or hexagonal, using processes like bending, forging, or machining. This versatility allows round bar steel to be used in a wide range of applications, from simple components to complex structures.

- Cost-Effective Solution: Compared to other metals like stainless steel, round steel is a relatively affordable material. It offers a balance of strength, durability, and cost, making it a practical choice for many projects.

The Manufacturing Process

Round bar steel undergoes a series of manufacturing steps to achieve its desired properties and characteristics:

- Steelmaking: The process begins with steelmaking, where molten iron is combined with carbon and other alloying elements in a furnace. The composition of the steel determines its final properties, such as strength, hardness, and ductility.

- Continuous Casting: The molten steel is poured into a mold and cooled to form a continuous billet. This process ensures a uniform structure and consistency throughout the steel.

- Hot Rolling: The billet is heated and rolled into a round shape to the desired diameter. Hot rolling improves the mechanical properties of the steel and reduces its internal stresses.

- Cooling: The rolled bar is cooled to room temperature. This cooling process can be controlled to achieve specific properties, such as hardness or ductility.

- Finishing: The final step involves finishing processes such as cutting, straightening, and surface treatment. These processes ensure the bar meets the required dimensions and specifications for its intended application.

Applications of Round Bar Steel

Round bar steel finds applications in a wide range of industries, including:

- Construction: Reinforcement bars, structural components, handrails, and fencing.

- Manufacturing: Shafts, axles, machine components, and tools.

- Automotive: Chassis, suspension components, engine parts, and exhaust systems.

- Agriculture: Fencing, gates, and farm equipment.

- Decorative: Balusters, railings, and furniture.

- Industrial Machinery: Gears, pulleys, and other mechanical components.

The Strength of Round Bar Steel

The strength of round bar steel is influenced by several factors:

- Carbon Content: The amount of carbon in the steel significantly affects its strength. Higher carbon content generally leads to increased strength but reduces ductility.

- Alloying Elements: Adding alloying elements like chromium, nickel, and molybdenum can enhance the strength and other properties of round steel. These elements can improve its resistance to corrosion, heat, and wear.

- Heat Treatment: Heat treatment processes, such as quenching and tempering, can significantly alter the strength and properties of round steel. These processes involve heating and cooling the steel to achieve specific microstructures and mechanical characteristics.

Durability and Corrosion Resistance

Round bar steel is known for its durability and resistance to wear and tear. However, its corrosion resistance can be affected by environmental factors. To enhance its corrosion resistance, various methods can be employed:

- Galvanizing: Applying a protective zinc coating to the surface of the steel prevents rust and corrosion.

- Painting: Coating the steel with a suitable paint or coating provides a barrier against corrosive elements.

- Alloying: Adding alloying elements like chromium and nickel can increase the steel’s resistance to corrosion.

Round Bar Steel vs. Other Metals

[Image: Comparison table of round bar steel with other metals, such as aluminum, stainless steel, and copper]

| Feature | Round Bar Steel | Aluminum | Stainless Steel | Copper |

|---|---|---|---|---|

| Strength | High | Moderate | High | Moderate |

| Durability | High | Moderate | Very high | High |

| Corrosion Resistance | Moderate | Good | Excellent | Good |

| Cost | Low | Moderate | High | High |

| Weight | Heavy | Light | Heavy | Heavy |

Choosing the Right Round Bar Steel

When selecting round steel for a specific application, consider the following factors:

- Required Strength: Determine the load-bearing capacity needed for the application.

- Corrosion Resistance: Assess the environmental conditions and select a grade or treatment that provides adequate protection.

- Machinability: Consider the ease of cutting, drilling, and shaping the steel.

- Cost: Balance the performance requirements with budget constraints.

Conclusion

Round bar steel is a versatile and durable material with a wide range of applications. Its strength, durability, and cost-effectiveness make it a popular choice for construction, manufacturing, and engineering projects. By understanding the factors that influence its properties and selecting the appropriate grade and treatment, you can ensure that round bar steel meets the specific requirements of your application.

FAQ

What is the difference between round bar steel and rebar?

Rebar is a specific type of round bar steel used for reinforcing concrete.

How is round steel measured?

It is typically measured by its diameter and length.

What are the common grades of round bar steel?

Common grades include A36, A572, and A992.

Can round steel be welded?

Yes, it can be welded using appropriate techniques, such as shielded metal arc welding (SMAW) or gas tungsten arc welding (GTAW).