Introduction

Stainless steel is a ubiquitous material in various industries, prized for its durability, corrosion resistance, and versatility. Among the many grades available, 304 stainless steel stands out for its exceptional qualities. In this blog post, we delve into the world of 304 stainless steel round bars, exploring their applications, properties, and benefits.

Understanding 304 Stainless Steel Round Bars

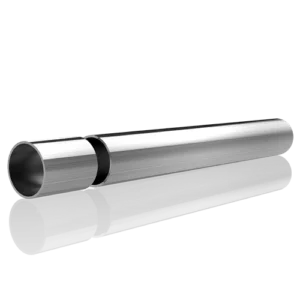

304 stainless steel round bars are cylindrical metal bars made from the alloy 304, a popular grade of stainless steel renowned for its excellent corrosion resistance and formability. Let’s explore the key characteristics of these round bars:

- Chemical Composition: The composition of 304 stainless steel round bars typically includes chromium, nickel, and a small amount of carbon. This composition contributes to its corrosion resistance and strength.

- Mechanical Properties: 304 stainless steel round bars exhibit impressive mechanical properties, including high tensile strength, excellent toughness, and good formability. These properties make them suitable for a wide range of applications.

- Corrosion Resistance: One of the most notable features of 304 stainless steel round bars is their exceptional corrosion resistance, especially in environments containing corrosive elements such as acids, alkalis, and chlorides.

- Heat Resistance: While 304 stainless steel is not as heat resistant as some other grades, it retains good performance at moderately high temperatures, making it suitable for many industrial applications.

- Aesthetic Appeal: Apart from its functional properties, 304 stainless steel round bars also offer aesthetic benefits. They have a bright, reflective surface finish that enhances the visual appeal of finished products.

Applications of 304 Stainless Steel Round Bars

The versatility of 304 stainless steel round bars lends them to a wide array of applications across various industries. Some common uses include:

- Construction: 304 stainless steel round bars are often used in construction for structural components, fasteners, and architectural elements due to their strength and corrosion resistance.

- Food Processing: In the food and beverage industry, 304 stainless steel round bars are preferred for equipment and machinery handling, processing, and storing food products due to their hygienic properties and resistance to corrosion from food acids.

- Chemical Processing: These round bars find extensive use in chemical processing equipment such as tanks, piping, and valves, where resistance to corrosive chemicals is crucial.

- Automotive: In the automotive sector, 304 stainless steel round bars are employed in exhaust systems, mufflers, and structural components due to their durability and resistance to heat and corrosion.

- Medical Devices: The medical industry utilizes 304 stainless steel round bars for the manufacture of surgical instruments, implants, and medical equipment due to their biocompatibility and sterilization capabilities.

Advantages of 304 Stainless Steel Round Bars

- Cost-Effective: Compared to some other stainless steel grades, 304 stainless steel round bars offer excellent value for money without compromising on quality.

- Wide Availability: 304 stainless steel is readily available in various forms, including round bars, sheets, and pipes, making it easy to source for different applications.

- Ease of Fabrication: These round bars are easy to machine, weld, and form, allowing for efficient fabrication processes and customization to meet specific project requirements.

- Low Maintenance: Once installed, 304 stainless steel round bars require minimal maintenance, reducing downtime and operational costs in various applications.

Case Study: Applications in the Food Industry

To illustrate the versatility of 304 stainless steel round bars, let’s examine their applications in the food industry through a case study:

| Application | Description |

|---|---|

| Food Processing Equipment | 304 stainless steel round bars are used to manufacture machinery such as mixers, conveyors, and blenders for food processing facilities. |

| Hygienic Surfaces | Surfaces made from 304 stainless steel round bars ensure compliance with strict hygiene standards in food production environments due to their smooth, non-porous finish. |

| Storage and Handling | Storage racks, shelves, and trays made from 304 stainless steel round bars provide durable and corrosion-resistant solutions for storing and handling food products. |

Conclusion

In conclusion, 304 stainless steel round bars offer a combination of exceptional properties, making them indispensable in a wide range of applications across diverse industries. From construction to medical devices, these round bars provide durability, corrosion resistance, and aesthetic appeal, making them a preferred choice for engineers, designers, and manufacturers worldwide.

FAQ

Q:What is the difference between 304 and 316 stainless steel?

A:While both grades are austenitic stainless steels, 316 stainless steel offers higher corrosion resistance, particularly in chloride environments, but at a higher cost compared to 304 stainless steel.

Q:Can 304 stainless steel round bars be heat treated?

A:Yes, 304 stainless steel round bars can be annealed to improve their mechanical properties, such as hardness and ductility.

Q:Are 304 stainless steel round bars magnetic?

A:While 304 stainless steel is generally non-magnetic in its annealed state, it may become slightly magnetic after cold working or during machining processes.

Q:What is the maximum temperature for continuous service of 304 stainless steel round bars?

A:304 stainless steel round bars can typically withstand temperatures up to 870°C (1600°F) in continuous service, with intermittent exposure to higher temperatures possible.

Q:Is 304 stainless steel round bar suitable for outdoor applications?

A:Yes, 304 stainless steel round bars exhibit excellent resistance to atmospheric corrosion and are commonly used in outdoor applications such as architectural elements, signage, and railing systems.