Introduction

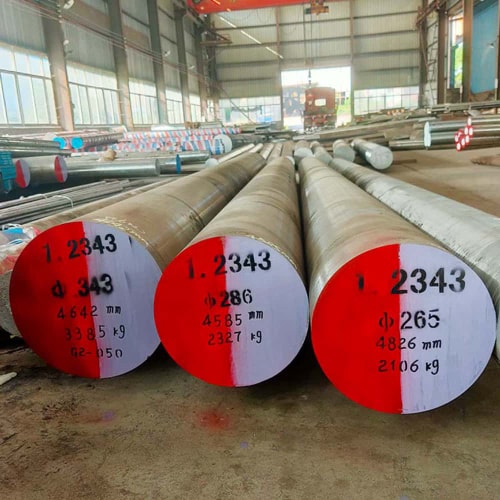

Hot rolled steel round bars are essential components in various industries due to their robust properties and versatile applications. Produced through hot rolling processes, these cylindrical metal rods offer high strength, durability, and excellent machinability, making them suitable for a wide range of structural and mechanical uses. This blog explores in detail the common uses and applications of hot rolled steel round bars across different sectors, emphasizing their key properties and benefits.

Properties of Hot Rolled Steel Round Bar

Hot rolled steel round bars exhibit several critical properties that contribute to their widespread use:

| Property | Description |

|---|---|

| Strength | Hot rolled steel round bars possess high tensile strength and excellent impact resistance, making them ideal for load-bearing applications. |

| Durability | They are resistant to corrosion and wear, which ensures longevity and reliability in various environments. |

| Machinability | Easy to shape, cut, and weld, allowing for precise customization and versatility in fabrication processes. |

| Heat Resistance | Maintains structural integrity at high temperatures, making them suitable for applications involving thermal stress. |

These properties make hot rolled steel round bars indispensable in sectors requiring sturdy and dependable materials.

Applications in Construction

In the construction industry, hot rolled steel round bars are integral components used in diverse applications:

- Reinforcement: They are commonly used in concrete reinforcement due to their high strength and bonding capabilities.

- Structural Support: Essential for constructing beams, columns, and other load-bearing structures where durability and reliability are paramount.

- Fabrication: Used in the fabrication of frames, stairs, and handrails due to their machinability and weldability.

Their ability to withstand heavy loads and harsh environmental conditions makes them a preferred choice in construction projects.

Industrial Machinery and Equipment

Hot rolled steel round bars play a crucial role in industrial machinery and equipment:

- Shafts and Axles: Used in the manufacturing of shafts and axles for machinery where strength and durability are critical.

- Gears and Cogs: Essential components in gear systems due to their robustness and ability to transmit torque effectively.

- Tool Manufacturing: They are employed in creating durable tools and equipment parts that require high wear resistance.

These applications highlight their importance in maintaining operational efficiency and reliability in industrial settings.

Automotive Industry

In the automotive sector, hot rolled steel round bars are utilized in various components and systems:

- Chassis Components: Integral to the construction of vehicle chassis for ensuring structural integrity and safety.

- Suspension Systems: Used in suspension and steering systems where durability and load-bearing capacity are essential.

- Engine Parts: Employed in the manufacture of engine components such as crankshafts and camshafts due to their strength and resilience.

Their contribution to enhancing vehicle performance and safety underscores their significance in automotive manufacturing.

Marine Applications

Hot rolled steel round bars are also crucial in marine environments for their corrosion resistance and durability:

- Shipbuilding: Used extensively in constructing ship frames, hulls, and decks due to their ability to withstand saltwater environments.

- Offshore Platforms: Essential for offshore platform structures where corrosion resistance and strength are critical.

- Mooring Equipment: Utilized in the fabrication of mooring lines and anchor chains to ensure reliability and safety at sea.

Their resilience against corrosion makes them indispensable in marine applications, where exposure to harsh conditions is prevalent.

Conclusion

Hot rolled steel round bars are indispensable materials in various industries, thanks to their exceptional properties and versatility. From construction and industrial machinery to automotive and marine applications, these components play a crucial role in ensuring structural integrity, durability, and performance. Understanding their properties and applications helps in making informed decisions regarding material selection and usage, contributing to efficient and reliable outcomes in diverse sectors.

FAQ

Q: What are hot rolled steel round bars?

A: Hot rolled steel round bars are cylindrical metal rods produced by hot rolling a billet of steel.

Q: What are the advantages of hot rolled steel round bars?

A: They offer high strength, durability, excellent machinability, and resistance to corrosion, making them suitable for a wide range of applications.

Q: How are hot rolled steel round bars used in construction?

A: They are used in concrete reinforcement, structural support, and fabrication of various architectural components due to their robustness and reliability.

Q: Are hot rolled steel round bars suitable for marine environments?

A: Yes, they are resistant to corrosion, making them suitable for shipbuilding, offshore platforms, and other marine applications.

Q: What industries rely on hot rolled steel round bars?

A: Construction, automotive, industrial machinery, and marine industries are major users due to their robust properties and versatile applications.