Introduction

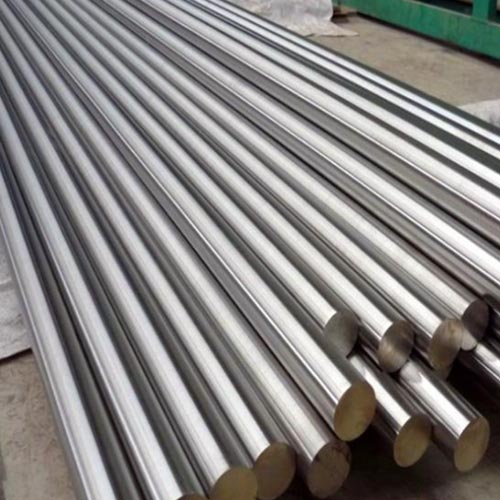

Stainless round bars are essential components in various industrial applications due to their exceptional properties and versatility. This blog explores the numerous benefits of using stainless round bars, their applications across different industries, and key considerations for selecting the right type.

Corrosion Resistance

Stainless round bars are renowned for their high corrosion resistance, primarily due to their chromium content, which forms a passive oxide layer on the surface. This oxide layer acts as a barrier against corrosive elements such as moisture and chemicals, making stainless round bars suitable for environments where durability and longevity are paramount. Industries such as marine, chemical processing, and food production rely on stainless round bars to maintain structural integrity and hygiene standards.

Stainless Round Bar Strength and Durability

One of the most significant advantages of stainless rounds is their exceptional strength and durability. They exhibit high tensile and yield strengths, making them suitable for structural applications where load-bearing capacity is crucial. Stainless steel’s inherent toughness allows it to withstand heavy mechanical stress and impact, making it ideal for applications in construction, machinery, and transportation sectors.

Heat and Chemical Resistance

Stainless round bars offer excellent resistance to high temperatures and chemical reactions, making them indispensable in industries such as petrochemicals, pharmaceuticals, and automotive manufacturing. The ability of stainless steel to maintain its mechanical properties at elevated temperatures ensures reliability and safety in critical applications like heat exchangers, exhaust systems, and chemical processing equipment.

Machinability and Fabrication

Stainless round bars are known for their good machinability and ease of fabrication. They can be readily welded, forged, and formed into complex shapes without compromising their structural integrity. This versatility makes stainless rounds suitable for manufacturing components ranging from intricate machine parts to large-scale structural elements in construction and aerospace industries.

Aesthetic Appeal

In addition to their functional benefits, stainless rounds offer aesthetic appeal. They can be polished to various finishes, including mirror-like, satin, and brushed finishes, enhancing their visual appeal in architectural and decorative applications. Stainless steel’s clean and modern appearance makes it a preferred choice for interior design, furniture, and artistic installations where aesthetics are as important as functionality.

Cost Efficiency

Despite potentially higher initial costs compared to other materials, stainless rounds offer significant long-term cost savings. Their durability and low maintenance requirements reduce lifecycle costs by minimizing repairs, replacements, and downtime. Industries benefit from improved operational efficiency and reduced environmental impact due to stainless steel’s sustainable and recyclable nature, contributing to overall cost-effectiveness.

Sustainability and Recyclability

Stainless steel is a sustainable material choice due to its recyclability and long lifespan. It can be recycled indefinitely without losing its inherent properties, making it environmentally friendly and economically viable. Industries increasingly favor stainless rounds for their ability to meet sustainability goals and reduce carbon footprint through responsible material use and lifecycle management practices.

Applications in Various Industries

Stainless round bars find extensive applications across diverse industries:

| Industry | Applications |

|---|---|

| Construction | Structural components, reinforcement bars |

| Manufacturing | Machine parts, tools, fasteners |

| Petrochemicals | Piping systems, heat exchangers |

| Food Processing | Conveyor systems, storage tanks |

| Aerospace | Aircraft components, fittings |

| Medical | Surgical instruments, implants |

| Automotive | Exhaust systems, engine components |

Conclusion

Stainless round bars play a crucial role in modern industrial applications due to their corrosion resistance, strength, durability, and aesthetic appeal. They contribute to operational efficiency, reliability, and sustainability across various sectors, making them an indispensable choice for critical applications in manufacturing, construction, and infrastructure development.

FAQ

Q:What are stainless round bars made of?

A:Stainless round bars are primarily made of steel alloyed with chromium, which enhances their corrosion resistance.

Q:What industries commonly use stainless rounds?

A:Stainless rounds are used in construction, manufacturing, petrochemicals, food processing, aerospace, medical, and automotive industries.

Q:How do stainless round bars compare to other materials in terms of cost-efficiency?

A:While stainless round bars may have a higher initial cost, their durability and low maintenance make them cost-effective over time compared to other materials.

Q:Can stainless rounds be recycled?

A:Yes, stainless steel is highly recyclable and retains its properties through multiple recycling processes.

Q:What are the different finishes available for stainless round bars?

A:Stainless round bars can be polished to various finishes including mirror, satin, and brushed, depending on the application requirements.