Introduction

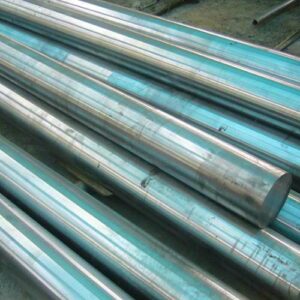

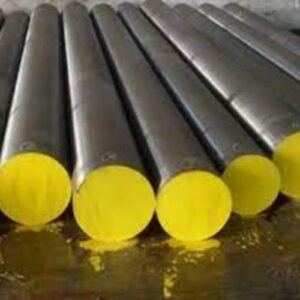

8620 steel, a medium carbon alloy steel, is renowned for its toughness, wear resistance, and machinability. These properties make it a popular choice in various engineering applications, from automotive components to industrial machinery. However, one often overlooked yet critical aspect of 8620 steel is its density. This blog post delves into the significance of 8620 steel density in engineering, exploring its impact on design, performance, and cost.

Density, defined as mass per unit volume, is a fundamental property of any material. For 8620 steel, density is influenced by its composition, which includes iron, carbon, and alloying elements such as nickel, chromium, and molybdenum. The specific density of 8620 steel can vary slightly depending on the exact composition and manufacturing process.

The Role of 8620 Steel Density in Engineering Applications

Weight Considerations

Weight reduction is a paramount concern in many engineering applications. Industries such as aerospace and automotive strive to minimize the weight of their products to improve fuel efficiency, reduce emissions, and enhance performance. The density of 8620 steel, along with other materials used in these applications, directly impacts the overall weight of the components.

By understanding the density of 8620 steel, engineers can optimize designs to reduce weight without compromising strength or durability. This can be achieved through various strategies, such as:

- Material substitution: Replacing denser materials with lighter alternatives, such as aluminum alloys or composites, can significantly reduce weight.

- Design optimization: Using advanced design tools and techniques to identify areas where weight can be reduced without affecting structural integrity.

- Manufacturing processes: Employing manufacturing methods that minimize material waste and optimize component geometry.

In addition to reducing weight, the density of 8620 steel also plays a crucial role in determining payload capacity. For equipment that must lift or move heavy loads, the weight of the components themselves can impact the maximum weight that can be handled. A lower density material, such as a certain grade of aluminum, might be considered if weight is a critical factor.

Stress and Strain Calculations

Density is a fundamental parameter in structural analysis and stress calculations. It is used in conjunction with other properties, such as modulus of elasticity and Poisson’s ratio, to determine the behavior of engineering components under load. Finite element analysis (FEA) and other computational tools rely on accurate density values to simulate the stress distribution, deformation, and potential failure modes of components.

The density of 8620 steel influences the stress and strain experienced by components in various ways. For example:

- Stress concentration: The distribution of stress within a component can be affected by its geometry and material properties, including density. Higher density materials may concentrate stress in certain areas, increasing the risk of failure.

- Fatigue life: Repeated loading can lead to fatigue failure in components. The density of a material, along with its modulus of elasticity, affects the stress distribution within a component and can influence its fatigue life.

- Vibration analysis: The density of a material affects its natural frequency and vibration characteristics. This is important in applications where vibration is a concern, such as rotating machinery.

Cost Implications

The cost of steel is often tied to its density. While higher-density steels may offer superior strength and durability, they can also be more expensive. Engineers must carefully consider the trade-offs between material cost and performance requirements when selecting 8620 steel or other materials for their designs.

In addition to material cost, the density of 8620 steel can also impact manufacturing costs. Denser materials may require more energy to machine or form, leading to higher processing costs. Factors such as part complexity, manufacturing tolerances, and production volume can also influence the overall cost of using 8620 steel.

The Density of 8620 Steel: A Comparative Analysis

| Material | Density (g/cm³) | Typical Applications |

|---|---|---|

| 8620 Steel | 7.85 | Gears, shafts, automotive components |

| Aluminum Alloy 6061 | 2.7 | Aerospace, automotive, construction |

| Stainless Steel 304 | 8 | Food processing equipment, chemical tanks |

Conclusion

The density of 8620 steel is a critical factor that engineers must consider when designing and manufacturing components. Its impact on weight, stress analysis, and cost makes it a fundamental property to understand. By carefully evaluating the 8620 steel density in relation to other materials and design requirements, engineers can optimize their designs for performance, cost, and durability.

FAQ

What is the average density of 8620 steel?

The average density of 8620 steel is approximately 7.85 g/cm³.

How does the density of 8620 steel compare to other steels?

The density of 8620 steel is similar to that of other medium-carbon alloy steels.

Why is the density of 8620 steel important in engineering?

Density affects weight, stress analysis, and cost in engineering applications.

Can the density of 8620 steel be altered?

While the overall density of 8620 steel cannot be significantly altered, it can be influenced by factors such as heat treatment and the addition of specific alloying elements.