Introduction

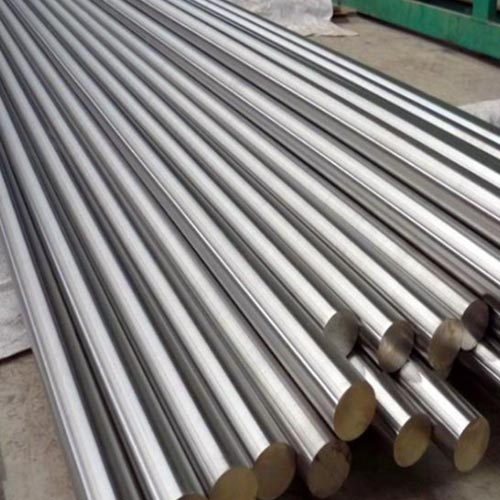

Stainless round bar, a cylindrical form of stainless steel, is a versatile material with exceptional corrosion resistance, strength, and durability. Its unique properties make it an ideal choice for a wide range of applications across various industries. In this comprehensive guide, we will delve into the diverse applications of stainless round bar, exploring its benefits and characteristics in detail.

Understanding Stainless Round Bar

Stainless steel, an alloy of iron and chromium, is renowned for its ability to resist rust and corrosion. When formed into a round bar, it offers additional advantages such as:

- High tensile strength: Enables it to withstand significant loads and stresses without breaking or deforming, making it suitable for structural components in buildings, bridges, and other infrastructure projects.

- Excellent ductility: Allows for easy bending and forming into complex shapes without compromising its structural integrity, making it ideal for applications such as handrails, balustrades, and decorative trim.

- Smooth surface finish: Reduces the risk of contamination and enhances hygiene, making it ideal for applications in industries such as food processing, healthcare, and pharmaceutical manufacturing.

Key Applications of Stainless Round Bar

Construction Industry

- Structural components: Stainless round bars are used in the construction of buildings, bridges, and other infrastructure projects to provide a durable and reliable foundation. Their high tensile strength and resistance to corrosion ensure the long-term stability and safety of these structures.

- Reinforcement: They are employed as reinforcement in concrete structures to enhance their strength and durability. By incorporating stainless round bars into concrete, engineers can improve the overall structural integrity and resistance to cracking and other forms of deterioration.

- Handrails and balustrades: Stainless round bars are commonly used to create stylish and durable handrails and balustrades for staircases, balconies, and decks. Their sleek appearance and resistance to corrosion make them a popular choice for both residential and commercial applications.

Automotive Industry

- Exhaust systems: Stainless steel round bars are used to manufacture exhaust pipes and mufflers due to their resistance to high temperatures and corrosive exhaust gases. They provide a durable and long-lasting exhaust system that helps to reduce noise and emissions.

- Suspension components: They are employed in the production of suspension components such as control arms and stabilizer bars. Stainless round bars offer excellent strength and durability, ensuring a smooth and comfortable ride.

- Decorative trim: Stainless round bars are used to add a touch of elegance to vehicle interiors and exteriors. They provide a durable and corrosion-resistant finish that complements the overall design of the vehicle.

Food Processing Industry

- Conveyor systems: Stainless steel round bars are used in the construction of conveyor systems for transporting food products due to their sanitary properties and resistance to corrosion. They provide a clean and hygienic environment for food processing, helping to prevent contamination and ensure food safety.

- Equipment components: They are employed in the manufacturing of food processing equipment such as mixers, blenders, and pumps. Stainless round bars offer excellent durability and resistance to harsh chemicals, making them ideal for use in food processing environments.

Medical Equipment

- Surgical instruments: Stainless round bars are used to manufacture surgical instruments such as scalpels, forceps, and retractors. Their durability, corrosion resistance, and smooth surface finish make them ideal for use in sterile environments.

- Medical implants: Stainless round bars are used to create medical implants such as screws, pins, and plates. Their biocompatibility and resistance to corrosion ensure the long-term success of these implants.

Chemical Processing

- Piping systems: Stainless round bars are used to manufacture piping systems for the transportation of chemicals and other corrosive substances. Their resistance to corrosion and high temperature ensures the safety and reliability of these systems.

- Equipment components: They are employed in the manufacturing of chemical processing equipment such as reactors, tanks, and heat exchangers. Stainless round bars offer excellent durability and resistance to harsh chemicals, making them ideal for use in these environments.

Aerospace

- Aircraft components: Stainless round bars are used to manufacture aircraft components such as landing gear, structural supports, and engine parts. Their lightweight, high strength, and corrosion resistance make them ideal for use in aerospace applications.

Marine

- Hull structures: Stainless round bars are used to create hull structures for ships and boats. Their resistance to corrosion and saltwater ensures the long-term durability of these vessels.

- Marine hardware: They are employed in the manufacturing of marine hardware such as winches, anchors, and rigging components. Stainless round bars offer excellent strength and durability, making them ideal for use in marine environments.

Oil and Gas

- Drilling equipment: Stainless round bars are used to manufacture drilling equipment such as drill pipes and drill collars. Their durability and resistance to corrosion ensure the reliability of these components in harsh environments.

- Pipeline components: They are employed in the manufacturing of pipeline components such as valves, fittings, and flanges. Stainless round bars offer excellent strength and corrosion resistance, making them ideal for use in oil and gas pipelines.

Table: Properties of Common Stainless Steel Grades Used in Round Bars

| Grade | Chromium Content (%) | Nickel Content (%) | Other Alloying Elements | Typical Applications |

|---|---|---|---|---|

| 304 | 18 | 8 | Molybdenum | Food processing, automotive, architectural |

| 316 | 16-18 | 10-14 | Molybdenum | Marine environments, chemical processing |

| 430 | 16-18 | – | – | Automotive trim, cookware |

| 303 | 18 | 8 | Sulfur, selenium | Free-machining applications |

Conclusion

Stainless round bar is an indispensable material in a wide range of industries due to its exceptional properties and versatility. Its combination of strength, corrosion resistance, and durability makes it an ideal choice for various applications, from construction and automotive to food processing, medical equipment, and more. As technology advances, we can expect to see even more innovative uses for stainless round bar in the future.

FAQ

What is the difference between stainless steel and carbon steel?

Stainless steel is an alloy of iron and chromium that is resistant to corrosion, while carbon steel is primarily composed of iron and carbon. Stainless steel is generally more durable and resistant to rust than carbon steel.

How is stainless steel round bar manufactured?

Stainless steel round bar is typically manufactured through a process called hot rolling, which involves heating the steel to a high temperature and then rolling it into a cylindrical shape. The bar can then be further processed through cold drawing or grinding to achieve the desired size and finish.

What factors should be considered when selecting a stainless steel grade for a specific application?

When selecting a stainless steel grade for a specific application, it is important to consider factors such as the required strength, corrosion resistance, and cost. Other factors to consider may include the intended environment, the need for specific properties like heat resistance or machinability, and any regulatory requirements.